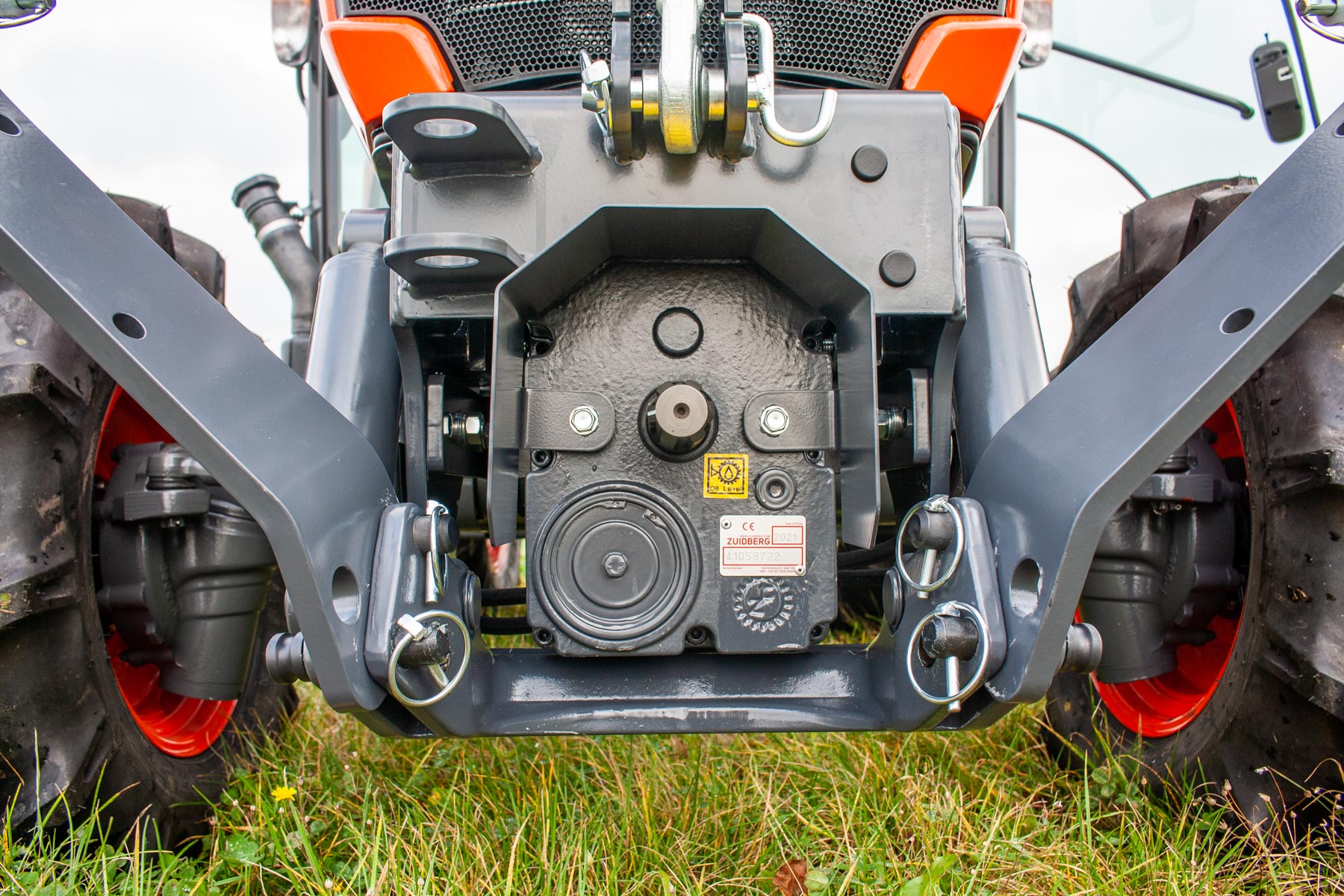

Zuidberg 'RL2' PTO

Maximum transmittable engine power

- Typical Zuidberg innovation in PTO technology

- Very compact design with high-tech solutions

- Maximum ease of use

- Long service life

- High operational safety

- The transferable power is in line with the tractor's engine performance

Available for the follwoing tractortypes with factory fitted front linkage:

- NewHolland T5

- CASE IH Vestrum

- Steyr Expert .

Quick and easy installation

Fuel-saving

Retention of manufacturer's guarantee for front linkage

Customised ease of use

- Compact design

- The drive shaft can be connected quickly and conveniently

- Fits within the warranty conditions of the front linkage

The 'RL2' in a nutshell:

- High operational safety

- Low maintenance

- Quick and easy installation

- Maximum engine power available

- Fuel-saving

- Retention of manufacturer's guarantee for front linkage

- Efficient and low noise level

Want to know more?

Receive our infosheet via e-mail.

Experience the benefits

Integrated blade clutch

The PTO has - connected to the input shaft - an integrated multi-plate clutch with forced oil lubrication with high cooling capacity. If the PTO is not engaged, the gears remain in rest position. The direct benefit is a fuel saving due to a low "0-load" (approx. 300W). The robust design of the clutch guarantees the highest operational safety.

No torque peaks

The proportional valve ensures a gradual and dosed engagement of the PTO.

Torque peaks are therefore minimal, which minimises the risk of machine wear.

Maximum cooling and lubrication

The gear on the output shaft has a baffle plate. This regulates the flow of oil in the gear area, ensuring 100% cooling and lubrication.

Oil filter

The oil filter is located at the top of the PTO and is therefore easily accessible for inspection and replacement. All particles larger than 10 microns are filtered out. The oil throughput guarantees optimum operation of the clutch and oil pump.

Where you can find us

your Zuidberg importer

What we are working on

Where you can find us

your Zuidberg importer

What we are working on

New in our product range: 2000rpm CW PTO for Kubota L1 & L2 serie (Stage 5) Click here for more . . .

Because of the upcoming national holidays in May, Zuidberg will be closed on the following . . .